Coil on Plug Coils

I get a lot of questions as to what coils are suitable for use with the Rae-San ignitions – and while some guidance in the forma of 2.5 to 5 ohms coils are suitable – I decided to do some investgation or readily available coil choices .

As part of this exercise i was looking for a standard type of coil fitment that I could recommend – and also looking for some suitable Coil On Plug (Stick Coils) that migth provide a sensible option – as some of these can be had quite inexpensively.

This page documents the Coil On Plug Results

You can find the Cinventional coil investigations investigations on this page – Conventional Coils

Tested Coils

Toyota Aftermarket Coils

These are available quite cheaply so were thought to possibly offer a chance to offer a full kit.

The Coil driver is built into the coil itself – removing load from the Rae-San module and just using a logic signal to driver them.

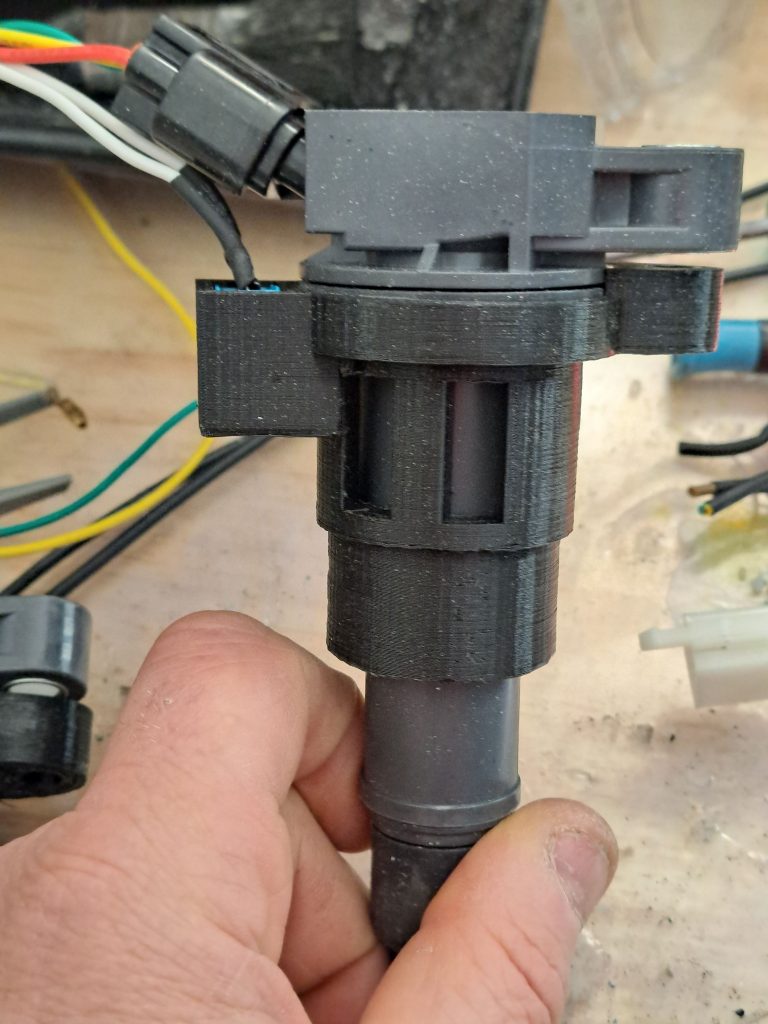

They need a capacitor mounted close to the COP and are a bit tall for the CX – requiring a mounting sleeve as in the photos.

Seedoo CDI Cops

These COPs are readily available and are shorter than most others on the market being designed for the marine engines in jet-skis.

They should mount well in the CX and not stick out like other options.

Denso TAI COPs

Ordered these to trial – and also as spares for my 1050 Sprint.

These are COPS used across a large range of fuel injected bikes from all manufacturers.

”’ssrrThe parameters of interest are resistance, charging time -in relation to the dwell time, spark strength and heat generated in both the Rae-San module and the coil itself.

Resistance

The resistance is a factor in that it determines the current drawn by the coil when it reaches saturation –

Once saturation is reached any addition dwell time is wasted as the coil is not storing any additional energy and must dissipate it as heat. As an example a 3 ohm coil with saturate at near 5Amps – and this is a power of nearly 75W into the coil – for no gain.

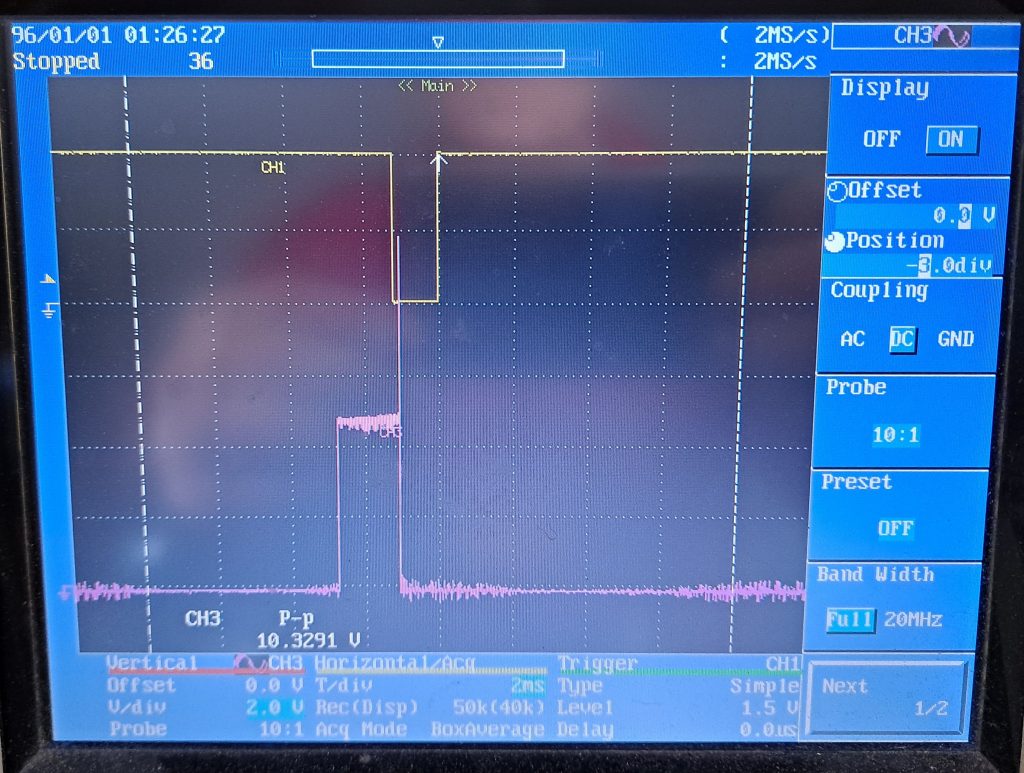

Dwell / Time to Charge

The time to charge the coils can vary greatly – as they have widely varying inductance’s (L). as a result the L/R time constant – the time taken to roughly reach 2/3 of the max for the coil – can vary as well. We want to aim for the dwell time to be about 1.5 – 2.0 times the L/R time constant so as to avoid wasting current and generating excessive heat.

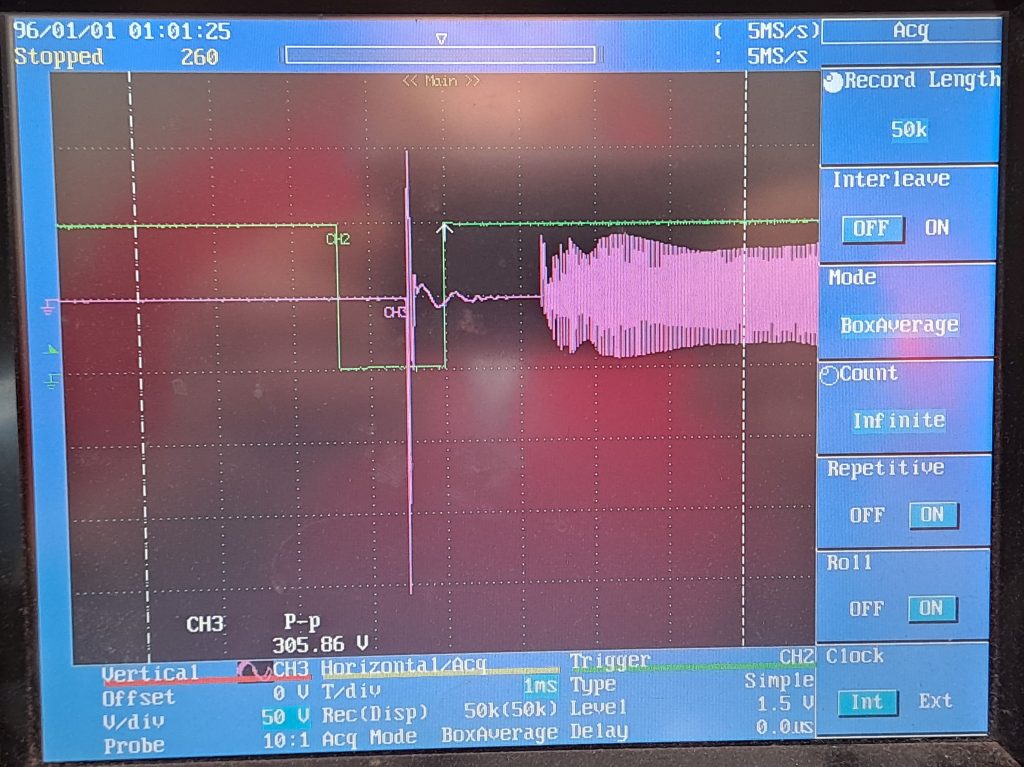

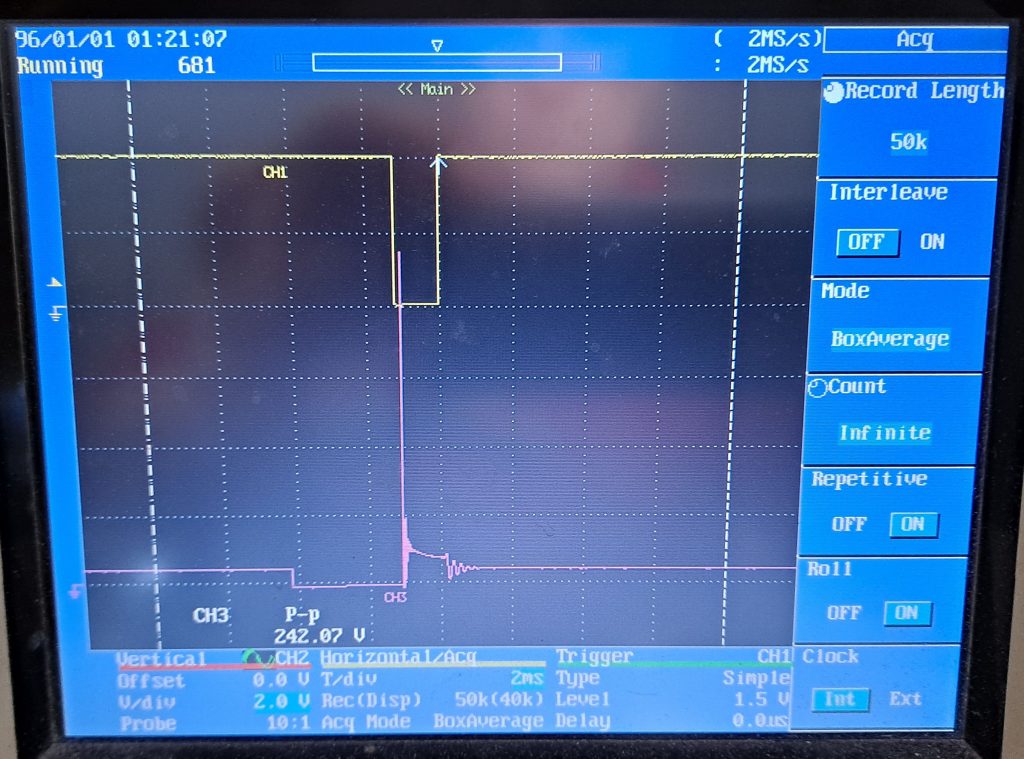

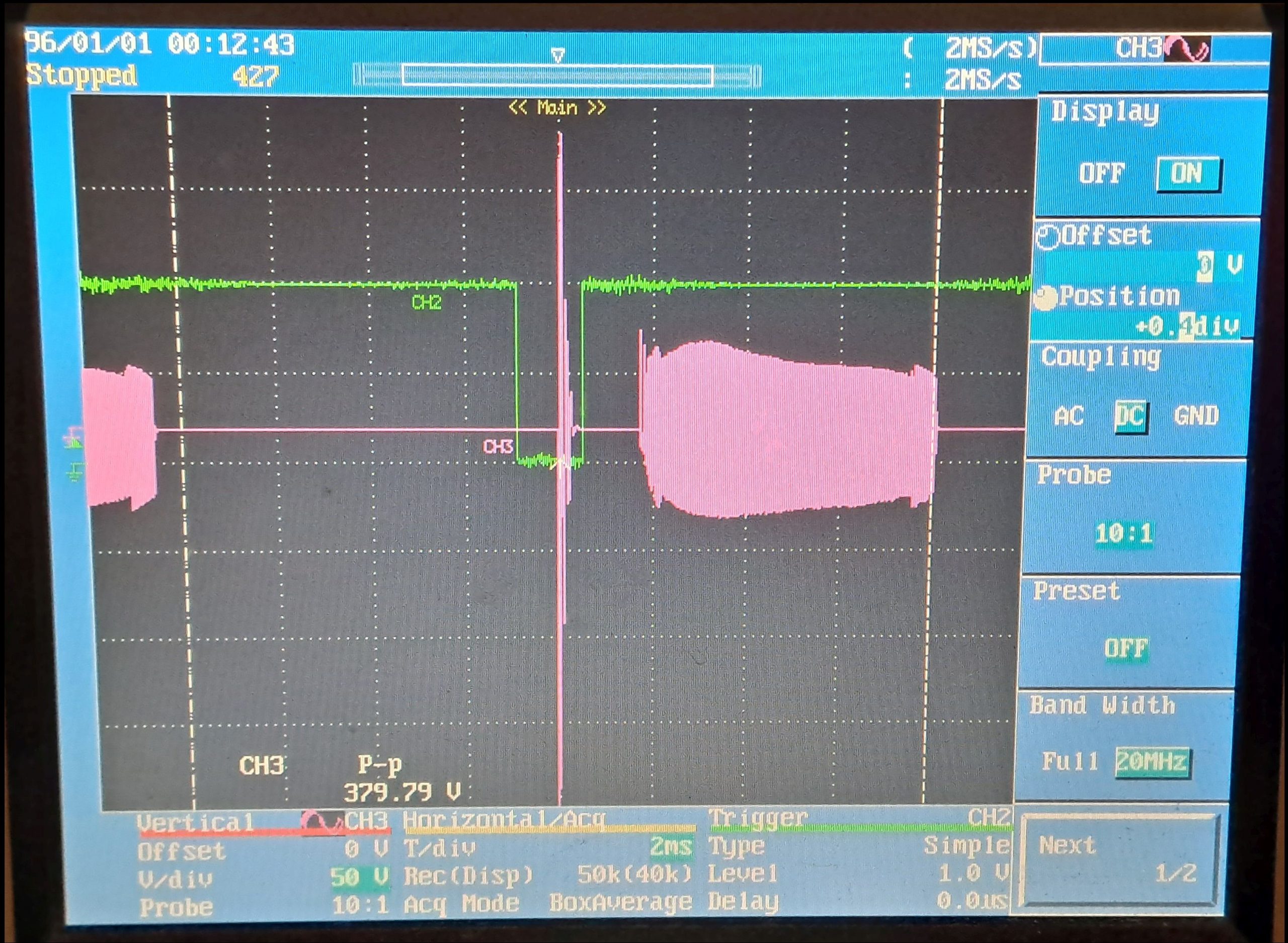

Spark Voltage

Without a high voltage probe this is a bit hard to measure directly – but I will grab a spark tester to be able to measure the gap jumped.

Typically the coils run about 100:1 turn ratio – so an estimate of the spark voltage an be made from the amplitude and duration of the spike on the drive side.

Spark Duration

This can be observed from the trace – and is directly related to how much energy is stored in the coil – the more energy the longer it takes to dissipate – note that a factor in this is the amount of resistance in the spark plug and cap – as this determines the current. No resistance will shorten the spark – making the spark current higher – I recommend always having a single resistor – either in the plug or in the cap – this gives the intended spark duration and generates less electrical noise – both back into the bikes own electrical system and to vehicles that you might be next to.

Coil Heat

This is the single biggest factor in the lifetime of the coils. They get hot – and then they sit above a hot engine – so they get even hotter. Any excess dwell time results in excess current – which results in excess heat.

At low RPM we don’t care so much – as the coil isn’t firing as often so overall a longer dwell here doesn’t add up to much.

At higher RPM we care A LOT. if you are running sustained operation at 6000 rpm say – that’s 100 fires a second ( on a wasted spark system)- every mS of extra dwell time once near saturation becomes 0.1S coil operation and another 7.5W of heat in the coil.

Module Heat

The MOSFETs used in the Rae-San Ignitions are good – but not perfect – they have a resistance om about 1/4 ohm – so at saturation of say a 5A coil – they each dissipate 6W for the short time -if we are driving say a COP coil of 1.2ohm – this rises to 25W for short peaks. Neither of these is a problem, but it is important to check whether additional heatsinking when mounting the module needs to be considered.

Test Results

Toyota Aftermarket Coil

Conclusion

These were driven from the V4.1 and V4.2 Rae-San modules – While the recommended dwell is 2.5ms for these coils – it was necessary to drop the dwell to 2.0m to ensure that the COPS were kept to reasonable temperature when running sustained operations at 6600rpm.

An interesting option – but due to the self heating of NON CDI Cops I am not pursuing any further.

Due to being logic driven – heating of the Rae-San module was zero.

Seadoo CDI COPs

Conclusion

A Version 3 module with GY6s was used to drive these with no issues, very little heat generation in plugs and good sparks.

A set is on one of CXPREAK’s bikes for further testing. Initial results are GOOD.

These work very well as a lover profile cop.

Denso TAI COP

Conclusion

At 1.2 Ohms and running a custom firmware with a 2mS dwell – good spark and manageable heat were acheived – sustained operation at 6500rpm yeilded a plug temp in the 90 – 100deg C range –

The New V4.2 module with improved grounding had no heat or other issues driving the COPS.

Coil On Plug Conclusions

TAI Coil on Plugs are usually not operated as wasted spark except for CDI COPS. For the TAI COPs they need very tight control on the dwell to limit the heat generated at higher RPM. Compared to a non-wasted spark system – the COP fires twice as often – effectively seeing double the RPM – so this could be the equivalent of up to 20000 RPM if it were non-wasted speark system.

CDI Coil on plugs dont store energy internally so don’t have anywhere near as much self heating and are commonly used on high reving two and 4 stroke engines running wasted spark.

As part of this exercise the need to drive High currents for COPs in the 1.2 ohm range allowed assessment of some areas where the board layout for the Rae-San V4 module could be improved – these were incorporated in a new revision and bench tested as version 4.2.

Also the software was updated to allow for another timing mode to provide tighter control of the dwell – this is rolled into the standard software.

If you want to use a COP – CDI is the recommended mode.

If you must use a TAI cop – then the dwell needs to be controlled down to the 2mS mark to avoid the COP cooking itself in sustained cruise or high RPM running.

Users wishing to use a TAI style COP will need to contact me for the 2ms firmware to be loaded.

Added some pics for the SeaDoo COP installed – in on bike testing currently.

updates – added murrays cop test